What can be customized in a keyboard

How does a build start and what is the difference between a store bought one and a custom build?

The Case

The case is self-explanatory; it encases the electronics of a keyboard to protect it and give it the desired appearance. The first major difference is, more often than not, the material that the casing is made of, the most popular ones currently being aluminium, brass, polished stainless steel, carbon fibre, or other materials like plastics (ABS), wood, etc. The possibilities for materials are unlimited. To increase a keyboard’s weight, brass or steel parts are added so as to achieve better sound absorption. Depending on the case, the mounting types can differ greatly. Top mounts or gasket mounts have become more popular due to their dampening effect and consistent feel. A cheat sheet was created in 2019 by Thomas Baart for the different types:

The form factor decides how many keys the keyboard has. Starting with a full size keyboard of 100% with around 104 keys, over to TKL (ten-key-less), or 80% keyboards where the numpad is missing are the more common sizes. There are also smaller-sized keyboards that come in 60%, or even 40%, that, depending on the layout, require a different amount of switches and have become increasingly available.

PCB

The heart of a mechanical keyboard, the printed circuit board or PCB, for short, transmits the input signals of the keyboard over to the connected device when pressing a switch, as well as the controls of RGB lighting, or stores information, such as layouts or layout mapping of a keyboard.

Hotswap or Solderable

In recent years, hotswap PCBs have grown more common in the keyboard market. They have special sockets so that you can click switches into place and pull them out without needing to solder and commit to one type of switch.

Solderable PCBs have most of their components already in place and one only has to solder the switch pins onto the PCB.

Plates

Covering the PCB is usually a plate. While a plate is not required when building a custom keyboard, the majority of mechanical keyboards come with one in different materials, shapes and forms. Common materials are carbon fibre, acrylic, aluminium, brass, stainless steel, or polycarbonate. While the materials mostly only affect the sound of a keyboard, the plate itself serves an important function; it secures switches onto the PCB and keeps them straight and in place. In the already mentioned mounting types, the possibility of securing the plate combined with the PCB to the case is not uncommon. Some of the most common layouts in the mechanical keyboard community are ANSI, ISO, WKL, Tsangan, and HHKB, and these layout options are limited by the PCB and plate compatibility. Some plates are also designed to be universal, allowing the user to select their layout of choice, and others are restricted to fit a single layout. To those that prefer a less stiff typing experience, half plates eliminate the section that alphanumeric keys, also called “alphas”, would normally clip into, allowing for flexibility around the alpha cluster. The removal of the alpha section on the plate means that the alphas will not create any reverberation through the plate, allowing for a much quieter key press

Switches

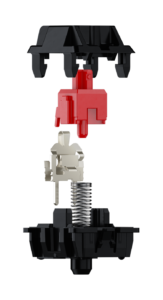

Mechanical switches are generally composed of the same parts, give or take a few pieces. That’s not to say that all switches are the same. Switch manufacturers often tweak to the base template to create their own unique switch flavours as well as material and switch travel distance. Note that the generalizations are based on Cherry MX mechanical switches.

The first major difference in switches are their type

- Tactile: Switches with a small bump or indent on the wing of the stem. When the switch is pressed, the stem slides against the leaf, and the uneven surface of the stem’s wing running against the leaf creates the tactile typing sensation.

- Linear: Switches with a straight wing stem. When the switch is pressed, the stem glides evenly against the leaf for a smooth, non-tactile typing sensation.

- Clicky: Switches with a sharp typing sensation and an audible click. Stem shapes vary, as the characteristic click sound may be produced by different mechanisms.

This picture is owned by cherrymx.com

By switching springs to different strengths, the feel of a switch can be changed and, therefore, so can the force needed to press down on a switch and to register a keystroke. As a hard and fast rule, heavier springs have higher actuation points. The exact actuation force required for each weight is a little more difficult to determine, as each manufacturer seems to follow its own standards.

Keycaps

To generlize sizes and measurments for keycaps, plates and pcbs, keycapsizing has been standarized through the community and manufacturers. The alphas, or alphanumeric keys, have the size of 1u. “U” stands for “unit” and is the reference to size larger keycaps. An ANSI “Enter” keycap, for example, is 2.25u, meaning it is 2.25 times larger than an alphanumeric key.

Stabilizer

Any keycap above the size of 2u needs something called a stabilizer since they are necessary for any build to keep the keycap from tilting and to ensure an even pressing and retracting of the key. The most known types are Cherry and maybe Costar style, which is either mounted to the PCB or the plate. Which stabilizer type you will need for your build is determined by the type of the cutout of your plate or what the PCB supports, as they need to be compatible with your stabilizers.

Keycaps

Now to the finishing touch of a keyboard and the final touch to the personalisation of your keyboard. Keycaps! ABS and PBT are the two most common materials keycaps are made of. As a newcomer, you might notice that most of the keycaps enthusiasts use are prefixed with GMK. GMK is a keycap manufacturer from Germany. They are known to make one of the thickest, highest quality, ABS keycap sets in the scene. Profile acronyms like Cherry, SA, MT3, KAT are not uncommon. This LINK will provide an overview of the different keycap profiles in which everyone’s taste can be matched. Most Keycap sets, that can be purchased via GB, have different Kits. Basekits usually include all necessary keycaps for a ANSI layout. Special Keycaps with different sizes, Novelties or ISO Keycaps can be purchased in seperate Kits.

Additional components

By adding additional components, builders try to control the acoustic properties, such as pinging. Therefore, dampening materials, such as foam, being placed in various areas inside a keyboard is rather common in keyboards smaller than 65%.

Additionaly, it is possible to film Switches with a thin rubberlayer between the top and bottom part of the Switch. This is done to improve sound- and vibrationabsorption properties.

One of the most important additional components that the enthusiast community has accepted and loved ever since, is a lubricant. Lubing stabilizers and switches is a common practice that aims to quiet down rattle and pinging and let the clean switch sound be in the spotlight.